Aluminum extrusion process definition

Aluminum extrusion molding applies strong pressure to the aluminum blank placed in the mold cavity, forcing the aluminum blank to undergo directional plastic deformation and extrusion from the die hole of the extrusion die, thereby obtaining the required cross-sectional shape, size and a certain Plastic processing method of parts or semi-finished products with mechanical properties. The principle of aluminum extrusion is similar to squeezing out toothpaste. Guangya has a 4,000-ton extrusion press, which can meet the processing and customization of various aluminum profile products.

Aluminum extrusion die

For product structure design engineers, we can design aluminum extrusion dies according to customer needs. Our engineers understand the basic extrusion die structure and the mechanism of how to shape different extrusion parts contour shapes, which helps in extrusion processing. When designing extruded parts, optimized design is used to reduce mold costs and improve extruded part production efficiency.

Advantages and applications of aluminum extrusion process

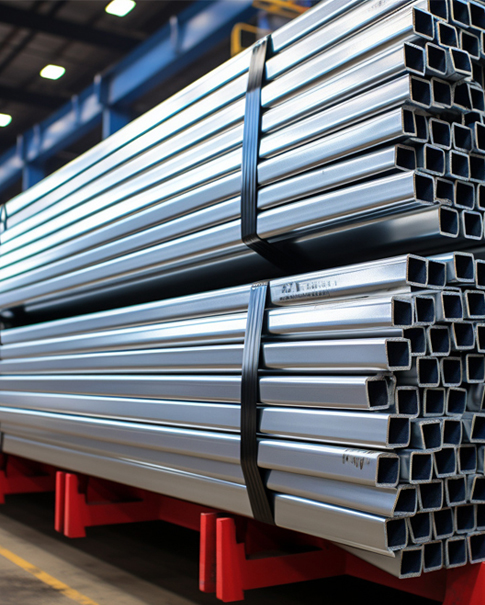

The aluminum extrusion process has the advantages of durability, lightness and strength, good thermal conductivity, fashionable appearance, easy secondary processing, short mold processing cycle, low cost, etc.

Its application scenarios are also very wide, such as: aviation and aerospace industry, transportation industry, building products industry, consumer goods industry, electronics industry, lighting industry, solar energy industry, etc.