You want answers that fit your needs. Custom aluminum extrusion profiles give you this choice. They let you control every part of your project. This saves you time and money from the beginning. You get more design choices, strong but light parts, and real savings. Custom aluminum extrusion profiles help you waste less material. They also make things faster to build. Here are the main benefits:

|

Benefit |

Description |

|---|---|

|

Design Flexibility |

Custom aluminum extrusion profiles match your special ideas and needs. |

|

Lightweight yet Strong |

You get strong parts without heavy weight. |

|

Sustainability |

Custom aluminum extrusion profiles use recycled materials and help the environment. |

|

Cost-effective Production |

Custom aluminum extrusion profiles save money over time and make work faster. |

Now you can see why custom aluminum extrusion profiles are great for any project.

Key Takeaways

-

Custom aluminum extrusion profiles let you change the design. You can make special shapes for your project. These shapes fit what you need.

-

These profiles are strong but not heavy. They work well for many uses. They are easy to move and use.

-

Custom aluminum extrusions help you use less material. This means you waste less and save money. They are made to be efficient.

-

Aluminum does not rust easily. It lasts a long time and needs little care. Your projects will stay good for years.

-

Picking custom aluminum profiles helps the planet. They use recycled materials. This lowers your carbon footprint.

Benefits of Custom Aluminum Extrusion Profiles

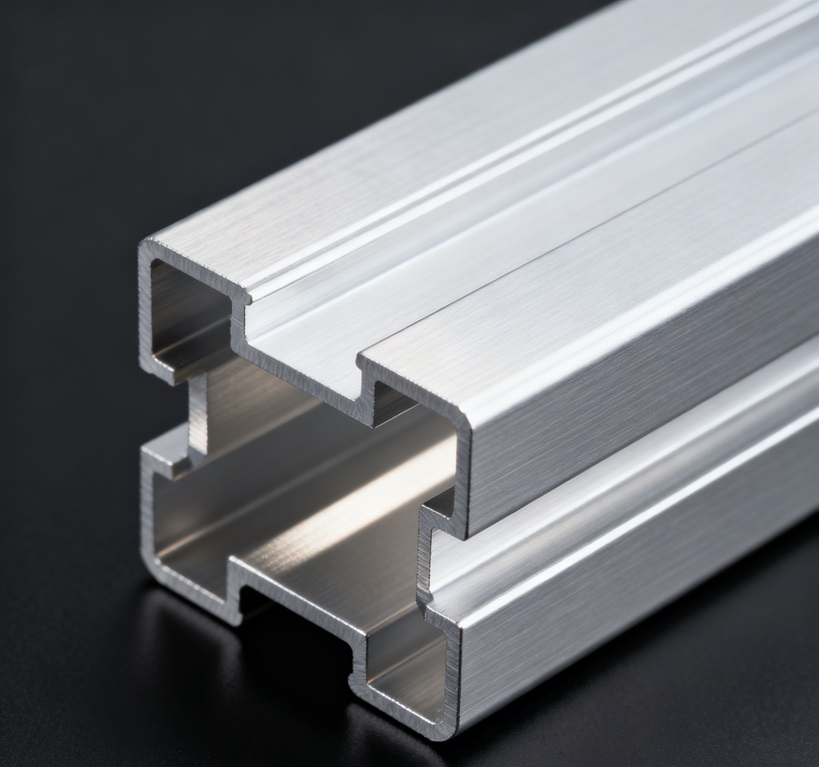

Design Flexibility

You want your project to be special. Custom aluminum extrusion profiles let you make shapes and sizes that fit your ideas. You can design parts that are more detailed than regular ones. This means you can put many pieces together into one. That saves time when you build things. You can pick finishes that make the parts last longer and look better. Custom aluminum extrusions help you try new things and meet special needs for any job. You get more ways to design and make your ideas real.

-

Custom aluminum extrusion profiles let you make special shapes and sizes.

-

You can design hard shapes that regular profiles cannot do.

-

Surface finishes make parts stronger and look nicer.

-

You can join many pieces into one, so building is faster.

-

Engineers like aluminum extrusion because it fits special needs and makes work better.

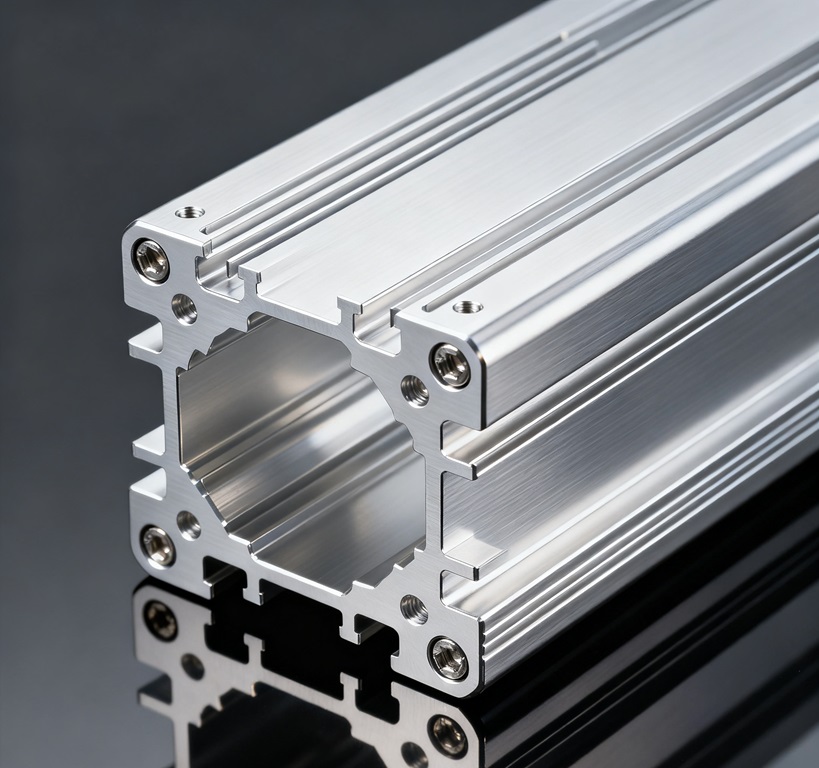

Superior Strength-to-Weight Ratio

You need parts that are light but strong. Aluminum extrusion profiles are tough and last a long time. They do not weigh much. Aluminum is about one-third as heavy as steel. It can still hold a lot of weight. This makes it good for buildings with many levels or tricky shapes. You get strong parts that are easy to move and put in place. Engineers like aluminum extrusion because it gives the best mix of strength and weight for hard jobs.

-

Aluminum extrusion profiles can hold a lot of weight.

-

You get light parts that are still strong.

-

Building projects are easier to put together and move.

-

Engineers like aluminum extrusion for its great strength and light weight.

Material and Cost Efficiency

You want to save money and not waste stuff. Custom aluminum extrusion profiles help you use materials well. Near-net shape manufacturing gives you parts close to your final design. This means you waste less material. Special dies help use more of the raw material and make less waste. You spend less on extra cutting or shaping. Tooling costs for custom aluminum extrusions are lower than other ways. You can cut down on building work by up to 60% because you put many parts into one. Engineers like aluminum extrusion because it saves money and works well.

|

Benefit |

Description |

|---|---|

|

Minimizes Waste |

Custom aluminum extrusion profiles make less waste by making near-net shapes. |

|

Reduces Additional Fabrication |

Cuts out extra steps like welding, so you spend less money. |

|

Precise Designs |

Lets you use less material but keep parts strong, so you save. |

-

Near-net shape manufacturing means less extra cutting.

-

Special dies help use more material.

-

Faster building times mean lower costs.

-

Engineers like aluminum extrusion for saving material and money.

Corrosion Resistance and Durability

You want your project to last a long time. Aluminum extrusion profiles do not rust like steel or rot like wood. You can use anodizing to make the protective layer even better. Paint or chromate conversion coatings add more protection. Sacrificial anodes and electrochemical insulation keep your profiles safe in tough places. Fluorocarbon wood grain aluminum profiles last over ten years outside. Wood needs more care and does not last as long. You spend less on fixing or replacing things. Engineers like aluminum extrusion because it is strong and lasts in hard places.

|

Method |

Description |

|---|---|

|

Anodizing |

Makes the natural oxide layer on aluminum stronger to stop rust. |

|

Aluminum coatings |

Puts a barrier on the surface, like paint, to stop rust. |

|

Sacrificial anodes |

Uses metals like zinc or magnesium to protect aluminum from rust. |

|

Chromate conversion coating |

Adds a chromium layer to stop rust and help other coatings stick. |

|

Electrochemical insulation |

Stops rust when different metals touch by keeping them apart. |

-

Aluminum structures last longer than steel or wood.

-

Aluminum extrusion profiles need little care and last a long time.

-

Engineers like aluminum extrusion for not rusting and being tough.

Sustainability Advantages

You care about the planet. Aluminum extrusion profiles use recycled materials and help green building rules. More than 90% of aluminum gets recycled in many jobs. Making aluminum from scrap uses only 5% of the energy needed for new aluminum. The carbon footprint of recycled aluminum is 60% lower than before. Aluminum can be recycled again and again without getting worse. Custom aluminum extrusions help you get LEED certification and meet green goals. You get products that save energy, last longer, and make less pollution. Engineers like aluminum extrusion for projects that help the environment.

-

Aluminum extrusion profiles use recycled materials and save energy.

-

Aluminum can be recycled over and over and has a high recovery rate.

-

Custom aluminum extrusions help you meet green building rules.

-

Aluminum extrusion profiles save energy and last longer.

-

Engineers like aluminum extrusion for helping the planet.

Tip: Picking special aluminum extrusion profiles for your project helps you get better results, spend less, and be kinder to the earth.

Applications of Aluminum Extrusion Profiles

Construction and Architecture

You want your building to look good and last long. Aluminum extrusion lets you try many ideas in construction. You use these profiles for windows, doors, and balconies. They help save energy and make buildings strong. Architects like aluminum extrusion because it gives many design choices. You can pick finishes like anodizing or powder coating. These finishes protect against weather and match your style. Aluminum extrusion helps you make special shapes for big glass walls. It also makes your building look better. Aluminum is eco-friendly and can be recycled. This helps you meet green building rules.

-

Windows and doors: Save energy and last longer.

-

Facades and cladding systems: Protect your building and look modern.

-

Railings and fencing: Stay strong and resist corrosion.

Tip: Architects and engineers use aluminum extrusion for strong and beautiful designs.

Automotive and Transportation

You want cars that use less fuel and work better. Aluminum extrusion helps you do this. You can swap heavy steel parts for lighter aluminum extrusion. This makes cars lighter and saves fuel. You use aluminum extrusion for battery boxes and crash safety. Lighter cars make less pollution and drive better. The car industry likes aluminum extrusion for its strength and light weight. It also helps make cool shapes for new designs.

-

Lighter vehicles improve fuel efficiency.

-

Aluminum extrusion applications include battery boxes and crash management.

-

Replacing steel with aluminum saves energy and reduces emissions.

Electronics and Technology

You want your electronics to stay cool and last longer. Aluminum extrusion helps with this. You use custom profiles for cases, heat sinks, and LED lights. Aluminum moves heat away fast, so devices do not get too hot. You can design cases that protect from damage and weather. Aluminum extrusion lets you make shapes that fit your needs. It also resists rust and is easy to carry.

|

Benefit |

Description |

|---|---|

|

Strength |

Strong cases keep electronics safe. |

|

Lightweight |

Easy to move and install. |

|

Flexibility in Customization |

Make profiles that fit your needs. |

|

Thermal Conductivity |

Moves heat away quickly to keep devices cool. |

|

Corrosion Resistance |

Protects electronics in tough places. |

Industrial Uses

You want your factory to work fast and well. Aluminum extrusion helps many industries by making exact shapes and sizes. You use these profiles in car factories, planes, boats, and making goods. Aluminum extrusion gives you parts that fit well and work every time. You can add things like hinges and grooves to make them better. Aluminum extrusion is light, so shipping costs less. It also helps make lots of products quickly.

-

Automotive and aerospace: Reduce weight and improve fuel consumption.

-

Marine industry: Resist corrosion in water environments.

-

Automated production lines: Achieve precise, stable, and durable equipment.

Note: You get more value and trust when you pick aluminum extrusion for your factory needs.

Custom vs. Standard Aluminum Extrusion Profiles

Advantages of Customization

You want your project to be different from others. Custom aluminum extrusion profiles let you make what you need. You can put many uses into one part. This helps you save both time and money. The parts are strong and light, and they fit your plans. Custom profiles are good for making many parts at once. You use less material and spend less money.

-

You can make hard shapes and add many features.

-

The parts are strong but not heavy, which is good for light jobs.

-

Custom aluminum extrusion helps you save money and waste less.

Custom profiles help you fix hard problems in engineering. You can meet special needs in fields like aerospace and electronics. You can make parts with close fits and special shapes. This helps your project work well and look nice.

-

You can meet tough rules in aerospace and defense.

-

You can make parts that do more than one thing for aerospace.

-

You can use custom aluminum extrusion for hard designs in aerospace and defense.

Comparison with Other Materials

You want to choose the right material for your work. Here is how aluminum extrusion compares to steel and plastic:

|

Criteria |

Aluminum |

Steel |

Plastic |

|---|---|---|---|

|

Weight |

Very light and strong |

Heavy but very strong |

Light but not as strong |

|

Cost |

Often costs less than steel |

Usually costs more |

Cheaper because of raw materials |

|

Durability |

Great against rust and wear |

Strong but can rust |

Good for shocks but can break down |

Aluminum extrusion gives you parts that are strong, light, and last long. It does not rust like steel. It is stronger than plastic. You also save money and get a material that lasts.

When to Choose Custom Extrusions

Pick custom aluminum extrusion when you need special shapes or sizes. You get the most out of it when you need exact parts or want to waste less. Custom profiles are best for building, cars, electronics, and aerospace.

|

Scenario |

Benefit |

|---|---|

|

Precise shapes and sizes |

Helps you meet your project’s needs and work better. |

|

Design flexibility |

Lets you make special designs that standard profiles cannot do. |

|

Waste reduction |

Less material is thrown away, so you save money. |

|

Industries |

Used in building, cars, planes, electronics, and more. |

Tip: If your project needs close fits, special shapes, or must follow strict rules in aerospace, custom aluminum extrusion is the best pick.

Choosing Custom Aluminum Extrusions

Lead Times and Production Process

You want your project to finish quickly. Knowing how long it takes helps you plan. Custom aluminum extrusions take more time than standard ones. This is because you must approve designs and make special tools. You also need new molds for custom profiles.

|

Profile Type |

Average Lead Time |

|---|---|

|

Standard Profiles |

7 to 14 days |

|

Custom Profiles |

15 to 30 days |

Custom aluminum extrusions give you more control. The process has many steps to make sure everything is good.

-

You start by making a design with CAD software.

-

The factory uses CNC machines to make a custom die.

-

Workers get high-quality aluminum billets ready.

-

The billets are heated and pushed through the die.

-

The profiles are stretched to take away stress.

-

Saws cut the profiles to the right size.

-

Surface finishes like anodizing or powder coating protect and make them look nice.

Tip: Plan early for custom orders. The extra time means you get better quality and results.

Cost Considerations

You want to spend your money wisely. Many things change the cost of custom aluminum extrusions. The price of aluminum goes up and down in the world market. Hard designs cost more because they need extra work. Tooling costs matter since you need special dies. Worker pay and factory costs add to the price. Extra coatings or treatments also raise the cost. Shipping and order size can change what you pay.

|

Cost Factor |

Description |

|---|---|

|

Raw Material Costs |

The price of aluminum, which can change often. |

|

Design Complexity |

More detailed designs may raise costs. |

|

Tooling Costs |

Custom dies are an upfront investment. |

|

Labor and Overhead |

Includes worker pay and factory expenses. |

|

Finishing Processes |

Extra coatings or treatments for the final product. |

|

Logistics |

Shipping and handling to your location. |

|

Order Volume |

Bigger orders can lower the cost per piece. |

You save money when you order more pieces. Simple designs and finishes also help lower costs. Always ask your supplier for ways to save money.

Selecting a Supplier

You want a supplier you can trust. They should deliver on time and meet your needs. Start by writing down what you need for your project. Check if the supplier can do the job and handle your project size. Look for suppliers who care about the environment and use renewable practices. See if they have quality certifications like ISO 9001, IATF 16949, or AS9100.

A good supplier shows certifications like ISO 9001 for quality. For cars, look for IATF 16949. For planes, look for AS9100. ISO 14001 and ISO 45001 mean they care about the environment and safety.

You get better results with a supplier who cares about quality and the planet. Ask about their past work and customer reviews. Pick a partner who helps you reach your goals and gives good results every time.

You want your project to turn out great. Custom aluminum extrusion profiles help you with design, strength, and saving energy. You also get sustainability at every stage. Sustainability is important when you plan, build, and finish your project. It helps you save money and care for the earth. Sustainability means using recycled materials and making less waste. It helps you follow green building rules. Sustainability saves energy and makes products last longer. It lowers your carbon footprint. It makes your project special. Sustainability helps you reach your goals. It gives you more value. It makes people trust your work. Sustainability is important for the future.

|

Criteria |

Description |

|---|---|

|

Raw Material Cost |

The price of aluminum changes with supply and demand. |

|

Profile Design and Tolerances |

Hard shapes and close fits change cost and quality. |

|

Tooling Costs |

Making extrusion dies costs money once, based on design. |

|

Surface Finishing and Operations |

Extra steps like anodizing or machining add to the price. |

|

Order Quantity Impact |

Bigger orders make each part cost less. |

|

Quality Control Measures |

Checks at every step make sure you get the best quality. |

You should pick custom aluminum extrusion profiles for your next project. You get the best mix of sustainability, performance, and value.

English

English  français

français  Deutsch

Deutsch  русский

русский  español

español  português

português  العربية

العربية  Melayu

Melayu  ไทย

ไทย  Indonesia

Indonesia  हिंदी

हिंदी

IPv6 network supported

IPv6 network supported