1.Various processing methods ♦ Aluminum alloys can be plastically deformed by various methods such as hot processing and cold processing. This includes various processes such as pressure processing, stretching, bending, etc. ♦ Through these processes, aluminum alloys can change their shape under different temperatures and conditions to meet complex processing requirements. 2. Easy to form ♦ Aluminum alloy materials are suitable for various forming processes such as casting, forging, extrusion, etc. ♦ These forming processes can produce aluminum alloy parts and components with complex shapes and precise dimensions. 3. Tensile strength and high impact strength ♦ The plasticity of hard aluminum alloys is manifested as low tensile strength, usually between 200~350MPa. Although the tensile strength is relatively low, the alloy contains trace elements, which makes it have a higher impact strength. ♦ This characteristic enables aluminum alloys to better resist deformation and damage when subjected to impact or external force. 4. Deformation rate, compressive resistance and tensile properties ♦ The plastic properties of aluminum alloys include deformation rate, compressive resistance and tensile properties. These properties enable aluminum alloy to maintain good deformation ability during processing and adapt to various processing requirements. 5. Plasticity under the influence of temperature ♦ Temperature is one of the important factors affecting the plasticity of aluminum alloy. When the material temperature is higher than the Curie temperature of the alloy, its deformability is enhanced, and both tensile strength and tensile strength are reduced. ♦ This characteristic allows the plasticity and processability of aluminum alloy to be effectively improved by adjusting the temperature during processing. According to the above, aluminum alloy has strong plasticity and is very suitable for making various shapes and designs in architectural decoration, and making corresponding combinations according to the overall style. Therefore, aluminum alloy is an indispensable material for building interior decoration.

Read MoreThe 19th ALUMINIUM CHINA Exhibition opened on July 3 at the Shanghai New International Expo Center. The exhibition brought together high-quality resources in the aluminum industry and terminal application fields at home and abroad, attracted more than 600 companies from more than 80 countries and regions around the world to compete on the same stage, and fully demonstrated the innovative technologies and excellent products of the aluminum industry chain. The booth of Guang Ya Aluminum is located in Hall 3 B30. The unique and creative booth design cleverly combines the brand concept with the product charm. The company's images and physical samples show Guang Ya Aluminium's latest achievements to global merchants. On the first day of the exhibition, the Guang Ya Aluminium team provided customers with a full range of aluminum application solutions with a professional attitude and patience. From process, technology to product services, all of them reflect its deep industry heritage and professional strength. This exhibition not only enhanced the brand influence of Guang Ya Aluminium, but also laid a solid foundation for its future market expansion and business growth.

Read MoreCraftsmanship competition, full firepower; hardcore PK, full process super combustion. On May 23rd, a series of celebrations for the 40th anniversary of the establishment of Knowledge City Group and the first "Zhixing Cup" labor skills competition for aluminum production were held at the Foshan Sanshui Base of KCI Guangya Aluminum. This aluminum production frontline labor skills competition is the first competition of the first "Zhixing Cup" labor skills competition. The competition revolves around the aluminum production line and carefully sets up three major competition projects: inspection, forklift, and crane. The labor skills competition is an important platform for employees to showcase their skills, improve their quality, and grow into talents. Since its establishment, Guangya has always adhered to the core of skill cultivation and talent development as the guide. This skills competition is not only a comprehensive review of the skill level of Guangya employees, but also a powerful promotion to improve the overall quality of the company, promote technological progress and innovation, and provide solid technical support for the company's sustainable development and industrial upgrading. With the start of the forklift on site, the cannon salute and thunderous applause, the competition officially opened. The competition is tense and intense, with various professional contestants showcasing their skills and talents. In the forklift competition, the driver showed his magic skills by operating the forklift to carry the red wine cup with half a cup of red wine and fold up the arhat. Such a delicate job, even a forklift can do it! At the crane competition field, employees use remote control to command a crane that is over ten meters high, carrying buckets to cross various obstacles. This labor competition has provided a good platform for all participants to exchange skills, exchange ideas, learn from each other, and seek common development. It also demonstrates Guangya's determination to vigorously promote the spirit of model workers, labor, and craftsmanship.

Read MoreOn April 8th, under the guidance of the Chongqing Liangjiang New Area Management Committee and hosted by the AUPUP Platform, the 2024 AUPUP Conference of "Five Lights Together, Gathering Stars and Flashing" was grandly held in Chongqing. Guangya Aluminum, as the preferred partner of the AUPUP platform, was invited to attend this conference and won the "Spotlight Award". More than 400 enterprises participated in the conference, with over a thousand distinguished guests gathered together. Through in-depth exchanges and discussions, we achieved the integration of government and enterprise advantages, jointly promoted the upgrading and development of the industrial chain, shared excellent resources and management experience, explored new opportunities and challenges for development in the new era, and sought new paths for high-quality development. To express our gratitude to our outstanding partners who have fought alongside AUPUP, the conference has set up a special recognition segment for the "Five Stars Together". Guangya Aluminum has successfully won the "spotlight award" for its strategic partnership with AUPUP over the years. The award not only represents the high recognition of Guangya Aluminum's products, technology, and services by Chongqing Liangjiang New Area and AUPUP Platform, but also embodies the expectation of further deepening cooperation between the two sides in the future.

Read MoreProduction standards, industrial aluminum profiles produced by legitimate manufacturers all comply with the European production standard ISO9001 quality management system. 90% of the standard industrial aluminum profile raw materials on the market are 6063-75. 6063 refers to the license plate of aluminum alloy, 775 is the classification mark for heat treatment, and it is artificially aged after cooling at the forming temperature. The standard slot width for industrial aluminum profiles is divided into slots 6, 8, and 10, which need to be selected according to your installation needs. It should be noted that interior accessories must be selected according to the slot width of the profile, otherwise there may be situations where the accessories cannot be inserted or fall off after being inserted. The material standard size produced by aluminum profile manufacturers on the market is 6.02 meters, so it can be cut freely within 6 meters. If you want a length of more than 6 meters, you need to produce it regularly. The cutting tolerance of most manufacturers on the market is plus or minus 0.5 millimeters. Cutting loss. Manufacturers who value quality usually cut a knife at both ends of the material before cutting, in order to ensure the verticality and flatness of the cutting surface. The cut material head, tail, and aluminum wire produced during cutting are commonly referred to as cutting losses

Read MoreThis exhibition is an international trade exhibition dedicated to building materials, HVAC, doors and windows, floors, and solar glass and aluminum materials. It is hosted by ElanExpo, a Türkiye exhibition company. Through magazines, televisions, etc., the exhibition is promoted. The effects of the exhibitions held are very remarkable. The construction industry is one of the important pillars supporting Nigeria's economic development, and the Lagos International Building and Building Materials Exhibition in Nigeria provides an excellent opportunity for foreign businesses to explore the Nigerian market. With an exhibition area of 5000 square meters, more than 200 exhibitors from 25 countries including China, India, the United Arab Emirates, South Korea, Saudi Arabia, Spain, Türkiye, Germany, Italy, Yemen and other countries participated in the exhibition. During the exhibition, many local merchants came to the booth to exchange and negotiate. They expressed great interest in Guangya's related products and solutions, and the on-site negotiation atmosphere was lively. Through continuous communication, not only has Guangya strengthened its cooperation and communication with foreign clients, but it has also brought greater prospects for Guangya's "going global". In the future, Guangya will adhere to consistent quality and help improve the quality and efficiency of overseas business.

Read MoreQuality inspection of aluminum profiles mainly include the following aspects, 1. Chemical composition The chemical composition of aluminum is one of the important factors affecting its performance. Aluminum generally requires the main component to be high-purity aluminum, while containing small amounts of added elements such as copper, manganese, magnesium, silicon, etc., to adjust the structure and properties of aluminum alloys. 2. Mechanical properties The mechanical properties of aluminum materials include tensile strength, yield strength, elongation, impact toughness, and other indicators, which are related to the load-bearing capacity and durability of aluminum materials in use and are one of the most commonly used indicators. 3. Surface quality The surface quality of aluminum is an important indicator for evaluating the appearance quality of aluminum, mainly including defects, oxide skin, color, and gloss on the surface of aluminum. 4. Dimensional accuracy The dimensional accuracy of aluminum is an indicator for evaluating the dimensional deviation of aluminum, including straightness, flatness, angle, curvature, etc. The above indicators are the main contents of the quality standards for aluminum materials, and they are also key points that need to be paid attention to during the production and use of aluminum materials.

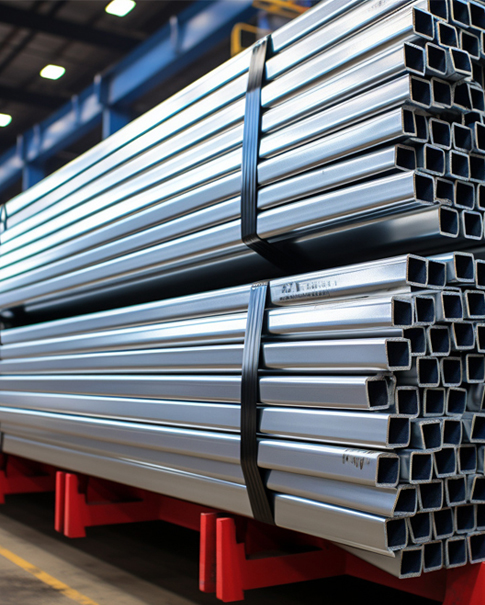

Read MoreIn the pursuit of green, low-carbon and sustainable development today, lightweighting has become an important direction for the transformation and upgrading of the manufacturing industry. Industrial aluminum profiles, with their excellent performance and wide application, are playing an important role as the "skeleton" and "muscle" of the lightweight era. Excellent performance and wide application Industrial aluminum profiles are aluminum materials with different cross-sectional shapes made of aluminum as the main raw material through processes such as melting, extrusion, and surface treatment. It has the advantages of light weight, high strength, corrosion resistance, easy processing, and recyclability, and is widely used in: Mechanical equipment: as frames, brackets, guide rails, etc., such as automated production lines, robots, machine tools, etc. Transportation: used for car bodies, chassis, interiors and other parts of automobiles, high-speed railways, subways, ships, etc., effectively reducing weight and improving fuel efficiency. Electronic appliances: used for radiators, housings, brackets, etc., such as computers, mobile phones, communication equipment, etc. Architectural decoration: used for curtain walls, doors and windows, partitions, ceilings, etc., beautiful and durable, energy-saving and environmentally friendly Technological innovation leads the future In recent years, with the advancement of science and technology and the continuous changes in market demand, the industrial aluminum profile industry has also been constantly innovating and developing: New materials: Develop new aluminum alloy materials with high strength, high toughness and corrosion resistance to meet the needs of different application scenarios. New processes: Use advanced extrusion, surface treatment and other technologies to improve product quality and production efficiency. New applications: Expand the application of industrial aluminum profiles in new energy, aerospace, medical equipment and other fields, injecting new vitality into the development of the industry. Green and low-carbon, broad prospects As a recyclable green material, the production and application of industrial aluminum profiles are in line with the national green and low-carbon development strategy. With the acceleration of the lightweight trend and the rise of emerging industries, the industrial aluminum profile industry will usher in technological innovation and industrial upgrading, and provide strong support for the high-quality development of the manufacturing industry. " Industrial aluminum profiles, as the "bones" and "muscles" of the lightweight era, are providing strong impetus for the development of all walks of life. I believe that in the near future, industrial aluminum profiles will shine in more fields and contribute to building a beautiful future of green, low-carbon and sustainable deve...

Read MoreIn modern industry, due to the characteristics of aluminum and aluminum alloy materials, their applications in aviation, machinery, automobiles, ships, and electronics industries are very extensive. In industrial production, aluminum and aluminum alloys need to undergo a series of processing and surface treatment in order to be made into the final product. During the processing, aluminum and its alloys undergo surface cleaning, storage, and metal casting processes, which may result in localized blackening and corrosion. What is the reason for local black spots on the surface of aluminum and aluminum alloys? 1.Using corrosive cleaning agents During the surface treatment process of aluminum and aluminum alloys, highly corrosive industrial cleaning agents are used, causing corrosion to the substrate surface of aluminum and aluminum alloys, resulting in blackening of the aluminum surface. 2.Unreasonable storage environment The storage environment for aluminum and aluminum alloys is unreasonable. Aluminum and aluminum alloys are stored in environments with high temperatures, salinity, and humidity. In such environments, aluminum and aluminum alloys are prone to oxidation and blackening. 3.Inadequate cleaning Inadequate or uncleaned cleaning of aluminum and aluminum alloy surfaces. After die casting and mechanical processing, aluminum and aluminum alloys are not thoroughly cleaned of cutting fluid, release agents, other corrosive components, stains, etc. on the surface of aluminum and aluminum alloys. These components remain on the surface of aluminum and aluminum alloys for a long time, leading to mold spots and localized blackening. 4.Failure to carry out post-processing in a timely manner The treatment process design of aluminum and aluminum alloys is unreasonable. After surface treatment such as cleaning and polishing, aluminum and aluminum alloys are not promptly treated for oxidation, resulting in corrosion, oxidation, and localized blackening of aluminum and aluminum alloys.

Read More