With a smooth surface finish, aluminium flat bar can be easily fabricated, making them ideal for construction, automotive, and manufacturing applications.

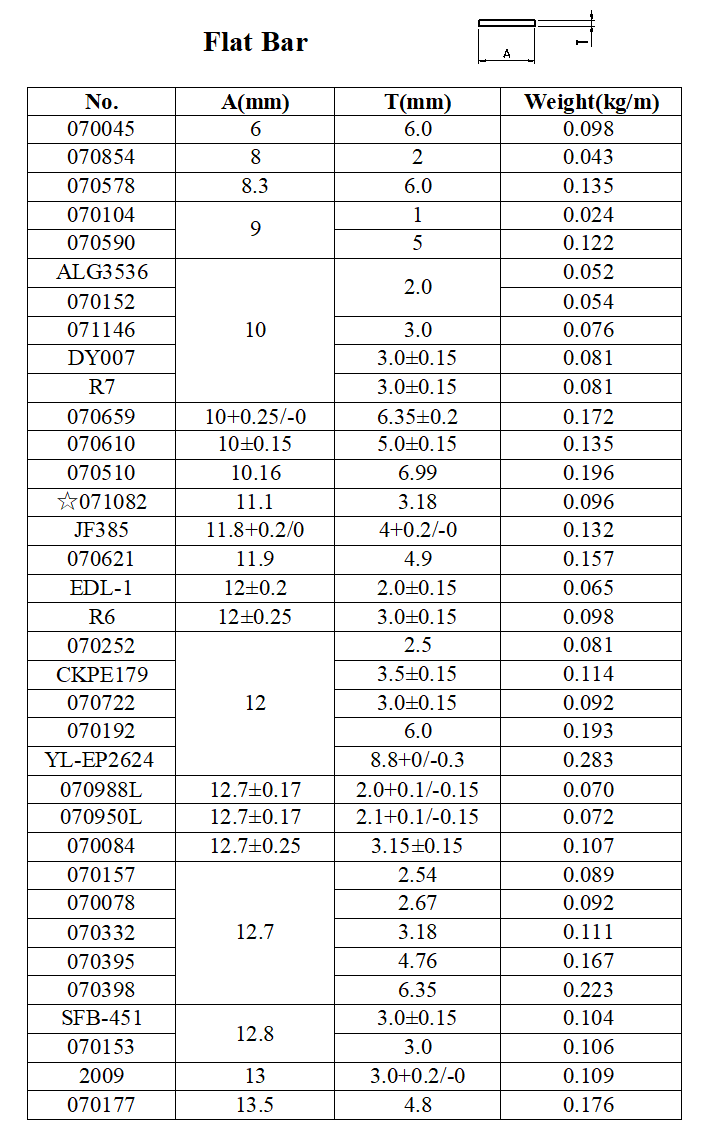

Guang Ya Aluminium can provide different sizes of aluminium flat bar that you need.

All of our aluminium flat bars are produced according to the standard EN755, GB5237 or ASTM B221 with the following alloys, 6005, 6060, 6061, 6063, 6082, etc.

→Contact Us for More Specification

1. Ingot casting

Ingot casting involves melting aluminum at about 780℃ and pouring it into molds to create solid blocks or ingots of aluminum. These

ingots serve as the raw material for further processing.

2. Extrusion

The process begins with the aluminum extrusion, where a cylindrical billet of aluminum is heated and forced through a die of the desired shape. The extrusion process uses high pressure to push the heated aluminum through the die, resulting in the desired profile shape.

3. Cooling

Once the aluminum has been extruded, it is quickly cooled using air or water cooling methods. This helps to stabilize the shape and strengthen the aluminum.

4. Aging

After cooling, the aluminum profiles may undergo an aging process, also known as precipitation hardening. Aging involves subjecting the profiles to controlled heat treatment, which enhances their strength and hardness.

5. Surface Treatment

Common surface treatment methods include anodizing, powder coating, and electrostatic coating. These surface treatments provide aluminum profiles with diverse functionalities and make them suitable for different applications across industries such as construction, automotive, and electronics.

6. Cutting and Machining

Once the profiles have undergone surface treatment, they may be cut into desired lengths using saws or other cutting tools. Additional machining processes, such as drilling, milling, or punching, can be performed to create specific features or holes in the profiles.

7. Quality Control

This involves inspecting the profiles for dimensional accuracy, surface finish, and mechanical properties. Samples may be tested for strength, hardness, and other relevant characteristics.

8. Packaging and Delivery

First, paste protective film on the visible surface of the profile, interweave each piece with foam paper, and then wrap enough pieces into bundles with shrink plastic film or kraft paper. Secondly, affix the customer's logo on both ends of the packaging. Last but not least, the profiles are packed in bulk into containers or bundled with wooden frames, and then placed on steel frames.