well designed to ensure the customers' satisfaction before, during and after sale.

More Info

well designed to ensure the customers' satisfaction before, during and after sale.

More Info

How Guang Ya Aluminium Industries Co., Ltd. Control the Quality of Your Aluminum Extrusion Guang Ya Aluminium Industries Co., Ltd. employs several quality control measures to ensure the quality of its aluminium extrusions. Here are the key methods we use, 1. Material Analysis: Guang Ya aluminium conducts thorough material analysis to verify the quality and composition of the aluminum used in the extrusion process. This analysis includes assessing the chemical composition, purity, and physical properties of the raw materials. By ensuring the high quality of the base material, we can maintain consistent extrusion quality. 2. Mechanical Testing: Guang Ya aluminium performs mechanical testing on the extruded aluminum profiles to evaluate mechanical properties. This may involve conducting tests such as tensile strength testing, hardness testing, impact resistance testing, and elongation testing. These tests help assess the structural integrity and performance characteristics of the extrusions. -Guang Ya Aluminium Testing Center- 3. Salt Spray Testing: Slat spray testing, also known as salt fog testing, is commonly used to evaluate the corrosion resistance of aluminum extrusions. This test involves subjecting the extruded profiles to a saltwater mist or fog for a specified period while monitoring the effects of corrosion. By conducting this test, Guang Ya aluminium can ensure that aluminum extrusions meet the required standards for corrosion resistance. 4. Cross-Cut Testing: Cross-cut testing is used to assess the adherence and durability of surface coatings or finishes applied to aluminum extrusions. This involves making intersecting cuts on the coating surface and inspecting it visually or through further testing, such as tape testing, to determine its adhesion quality. This helps Guang Ya aluminium ensure that the applied coatings provide the desired aesthetics, durability, and protection to extrusions. Cupping Test Artificially Accelerated Aging Test of Xenon lamp Irradiation Salt Spray Corrosion Resistance Test Profile Scanner Imported from Israel Uv Weather Resistance Test -Guang Ya AluminiumTesting Equipment- -Laboratory Accreditation Certificate-China National Accreditation Service for Conformity Assessment-

More Info

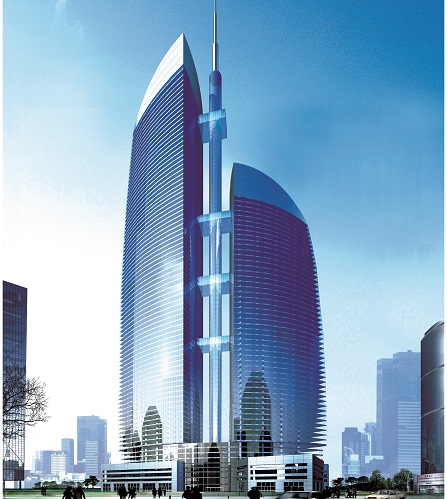

Custom Kinds Of Architectural And Industrial Aluminum Profile Our Advantage 70 Extrusion Production Lines (From 600 Tons to 5500 Tons) 10 Casting Production Lines 7 Powder Coating Production Lines 11 Anodizing and Electrophoresis Production Lines Total Annual Output can reach 500,000 tons. Our Service Professional and strong R&D force, with more than 300 technical personnel to suggest improvement for you about your custom product drawings. Professional production capacity, won a number of awards and certification, is the top five aluminum suppliers in China. Professional quality inspectors for each production process to ensure the quality and compliance of your products. Professional staff to match custom colors for you,make samples for your requirements. Professional mould development capabilities with our Guang Ya mould machining Center, which can satisfy all kinds of high-precision mould processing needs and provide customers with full-process services. Professional aluminium profile manufacturer experience, Since 1996. One-stop solution for any aluminum projects. Showing Room Of All Custom Aluminium Products Contact us now for professional services and products of aluminum profiles!

More Info

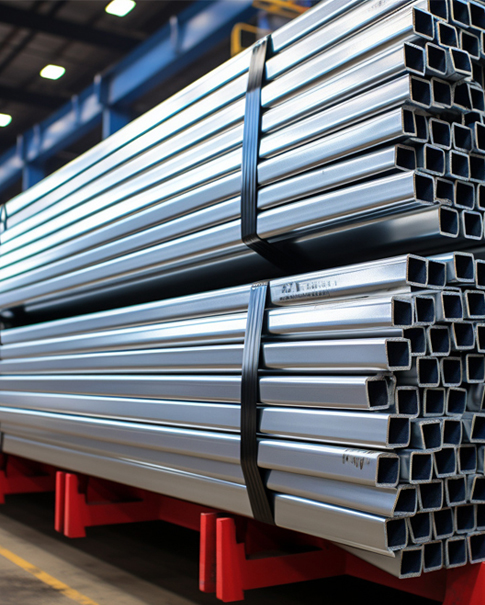

Custom Aluminium Extrusions What are Custom Aluminium Extrusions? Custom extruded aluminium is a manufacturing process where aluminium is forced at high pressure through a die that has been designed to create the desired cross-section. There are two major advantages of producing custom aluminium extrusions, while one is regarding the ability to create complex cross-sections, the other is related to the ability to economically create profiles that are meters in length. Guang Ya Aluminium has been producing custom aluminium extrusions for 27 years. As one of the professional custom aluminum extrusions suppliers in China, Guang Ya Aluminium strives to deliver high precision, complex profiles to customers from a wide range of industries. At Guang Ya Aluminium, close tolerances are possible and a number of finishes and fabrications are available. What are the Benefits of Custom Aluminium Extrusion? l Highly suitable to receive a wide range of finishes - paint, anodizing l Can easily be fabricated - cutting, drilling, punching, machining, bending, and other conventional fabrication methods l Can be joined to other aluminium products or to different materials by welding, soldering, brazing, bolts, rivets, clips, adhesives, clinching, slide-on, snap-together, interlocking joints l Can be designed for easy and reduced assembly l Can be designed and produced as complex and integral shapes l Can be designed and produced to close tolerances l Aluminum extrusions can be recycled and re-melted back into aluminum Why Choose Guang Ya Aluminium for Custom Aluminium Extrusions? l Guang Ya Aluminium has the flexibility, capability and expertise to complete your aluminium extrusion project. l Our ISO accreditation (ISO9001:2015 Quality management , ISO 14001:2015 Environmental management, ISO 50001:2018 RB/T 117-2014, ISO 45001:2018Occupational health and safety management, OHSAS 18001:2007Occupational health and safety management,) ensures quality throughout the process. Trust Guang Ya Aluminium to deliver your products on time and to specification. Surface Finishing Services Guang Ya Aluminium is a professional aluminum surface finishing service supplier that offers a wide range of high-quality aluminum finishing solutions for various industries. With years of experience in the field, Guang Ya Aluminium has developed a reputation for providing exceptional finishing services, including anodizing, electrophoresis, powder coating and PVDF. Guang Ya's team of skilled professionals is committed to providing its customers with customized solutions that meet their specific requirements. They use state-of-the-art equipment and advanced technology to ensure the highest quality finishes on every project they undertake. In addition to its exceptional finishing services, Guang Ya Aluminium is also dedicated to delivering exceptional customer service. They work closely with their clients to understand their unique needs and offer tailored solutions to ensure their complete satisfaction. Whether you are looking to finish aluminum parts for the automotive, aerospace, or any other industry, Guang Ya Aluminium has the expertise and capabilities to deliver outstanding results. So, if you are looking for a reliable and professional aluminum surface finishing service supplier, Guang Ya Aluminium is definitely worth considering. Aluminum Anodizing Anodizing aluminium is an electro-chemical process that provides a stronger, corrosion resistant surface and preserves a new appearance. The oxide film can be from 10μ to 25μ according to QUALANOD. Aluminum Powder Coating Powder coating is a surface treatment process used to make the surface corrosion resistance while providing a decorative appearance. Powder coating standard meets QUALICOAT . Aluminum PVDF Coating A resin-based coating provides protection against weathering, ageing and pollution. Aluminum Wood Grain Finish Wood grain finish starts with powder coating and laminates a wood film in the surface of aluminium extrusion to provide a wood appearance. Aluminium Fabrication Aluminum Extrusion Fabrication Capabilities Aluminium extrusion fabrication is vital for several different products. From automobiles to solar panels and supportive frames to electronics, aluminum can be found in nearly every industry. At Guang Ya, we keep improving our fabrication capabilities to meet your unique demands. With a wide selection of automatic and manual equipment, we ensure consistent and customized quality for aluminum fabrication services of all kinds. That means your job can be done right the first time. Over the past decades, we've worked closely with all kinds of companies related to aluminium extrusion. We have learned about the needs of different industries because we've provided customized aluminum fabrication and manufacturing solutions to meet their specifications. However, we know that every project is different even if they belong to the same industry. Made Ready For Assembly With Guang Ya, you can always get quality aluminium extrusions with great customer service for your projects. Everything we do is to make your part as easy as possible. As a one-stop-shop for all your aluminium extrusion sections, Guang Ya Aluminiumhas the capabilities to extrude, finish, fabricate and assemble components to your precise requirements. Fabrication is the process of adding features to a basic object by aluminium cutting, punching, bending, drilling, stamping, welding, or milling it into a product ready for assembly. Aluminum extrusions respond readily to fabrication. CNC Milling CNC Milling is an automated machining process that removes material from basic raw material. It has a wide range of applications in both architectural and industrial areas. The cutters of CNC milling machine are controlled by computer instructions, guaranteeing extremely high precision and repeatability. It can produce parts of nearly any shape from aluminum, steel, or plastics, producing a variety of custom-designed parts and products. Aluminum Precision Cut-To-Length Precision cut-to-length is the fabrication process to aluminum extrusions into two or more pieces by a CNC cutting machine. It can be straight cut or miter cut with certain angles. Guang Ya Aluminiumcan cut aluminum extrusions to any length with an extremely small tolerance. Aluminum Punching Punching is one of the most popular fabrication processes in aluminium industries. Window, door, lighting, enclosure, furniture, and many other applications of aluminium need to be punched. Aluminum Bending Aluminium bending is always requested in the industries such as automotive, construction, curtain wall, railing and furniture. There are various methods for bending aluminium. Aluminium roll bending is the most flexible and cost-efficient bending method. A profile is guided between three adjustable bending rolls and gradually bent in the desired radius.

More Info

Years Established

Number of employees

Factory Coverage

Global Sales Network