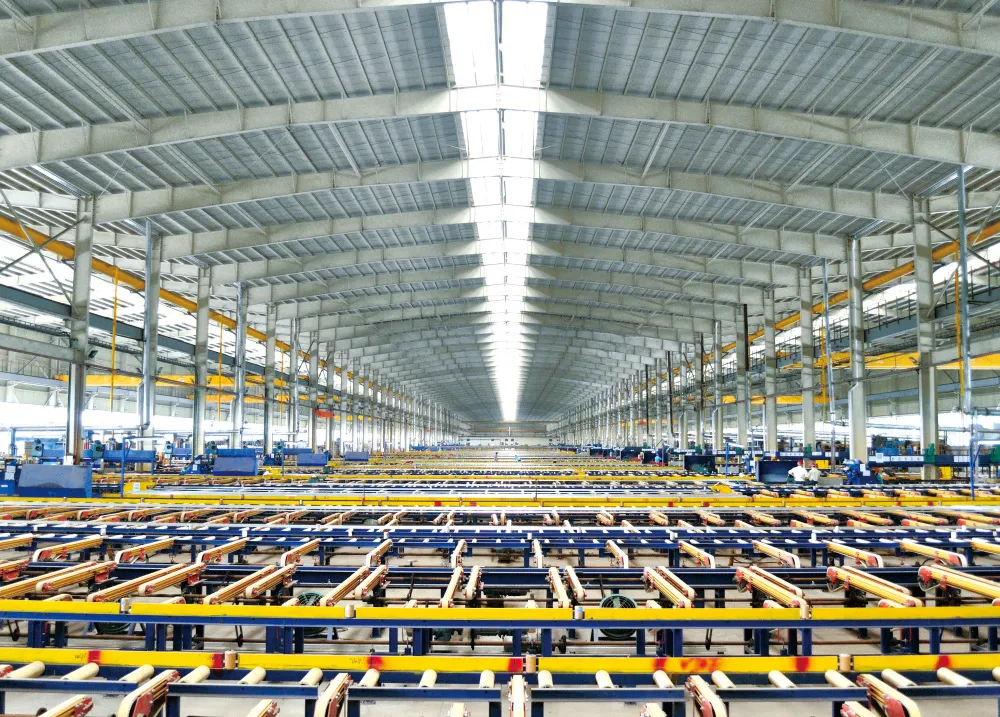

"Once, in the workshop of Guangya Holding Group, in Nanhai, Foshan, the capital of China's aluminum industry, the roaring extruder machine worked day and night, and the output of building curtain wall profiles flowed to landmark buildings across the country - Guangzhou New Baiyun Airport, Dubai Bay Gate, Abu Dhabi Central Market, Frankfurt Air Railway Center in Germany, Hong Kong-Zhuhai-Macao Bridge Hong Kong Border Inspection Station, Beijing Daxing Airport, etc. As soon as Master Guangya's hand touched, he knew whether the toughness of aluminum was up to par - that was the pride of an era. However, the wind in the market quietly changed"

As the real estate market continues to decline, the traditional construction market has been cooling down, and at the same time, under the "double carbon" goal, high-end equipment, new energy, new infrastructure and other industries have risen rapidly, and the demand for lightweight and high-precision industrial aluminum profiles is unprecedented.

Starting from 2023, the idea of transforming from architectural profiles to industrial profiles will be discussed at the internal strategy meeting of Guangya. But how easy is it to get out of the comfort zone of twenty or thirty years?

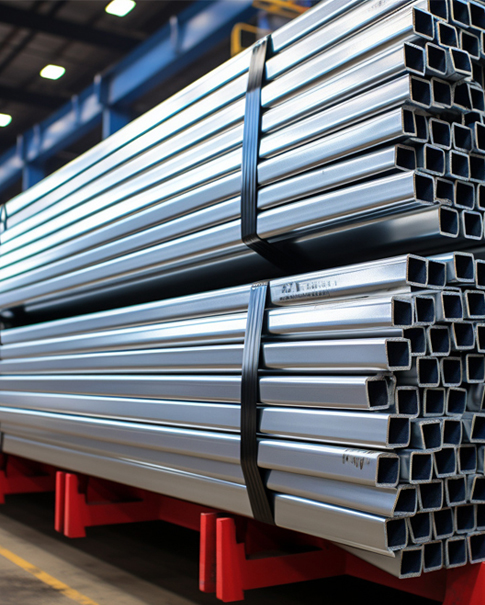

Industrial materials and building materials are fundamentally two roads, building profiles are "fast production and quick sales", industrial profiles are "slow work and fine work", the technical requirements are extremely high, the production efficiency is still one-third slower, the hardness, toughness, comprehensive requirements are higher, the concept and process must be rebuilt, Every trial and error is real money. Battery tray tolerance is 0.1mm – can we do it?

To turn or not to turn has become a matter of life and death in front of Guangya. Seeing the passage of time, the leadership team of the Knowledge City Group made up their minds: the situation must be broken! Traditional manufacturing, not afraid of slowing down half a beat, afraid of not moving. They reorganized Guangya's management, paid close attention to internal reforms, introduced professional talents, improved innovation capabilities, and forced the team to go out, "touch the market, and find orders".

The turning point came from Xiangxin Technology, a listed company in precision manufacturing. On the last day of September 2024, the person in charge of marketing at Guangya had returned to his hometown to prepare for the National Day holiday, and an emergency call came: Xiangxin intends to dock, but the evaluation will be started after the holiday. The vice president did not hesitate to rush the high-speed train back to the company overnight and led the team to prepare materials all night.

The real tough battle has just begun. Xiangxin took out the standard contract they never modified - the thick text was buried with dozens of strict clauses involving liquidated damages and fines...... Guangya was not frightened.

They formed a research team, studied and negotiated item by item, sent more revisions at one o'clock in the middle of the night, and the other party replied to their opinions at five o'clock in the morning. The two companies "rolled" out of tacit understanding. Two weeks later, for the first time in its history, Xiangxin revised the contract for its suppliers. Guangya relied on "dead knocks" to pry open the market, got the "ticket", and officially opened the door to the industrial materials market.

Outside the door is a more brutal challenge. The requirements for hardness, toughness and dimensional stability of industrial materials far exceed those of building materials, and trial production has repeatedly failed. In order to support this new order, on the one hand, Guangya's masters had to "forget" decades of experience and learn temperature measurement, speed control, and extrusion parameters from scratch; On the other hand, Guangya provides assistance for the transformation of industrial materials by introducing professional doctors and technical experts. The backbone technical team eats and lives in the workshop, adjusting alloys one furnace after another, measuring profiles one by one, exploring process breakthroughs step by step, and stepping out of a process road to success from failure.

Finally, the samples met the standard, and the small batch was put into production, and the mass production was stable. They gnawed on Xiangxin's orders, and thus entered the supply chain of Xpeng and BYD. Today, the Guangya workshop is still so roaring, but what flows on the assembly line is no longer only the doors, windows and curtain walls, but also the battery trays and body components of new energy vehicles - industrial skeletons with an accuracy of 0.1 mm.

From January to July this year, Guangya's industrial material sales exceeded 15,000 tons, in addition to 19 new energy vehicle projects, it also expanded home appliances and drone industrial material products. All this is inseparable from the determination to break the transformation and break the situation, and it is inseparable from the death of the people of the Knowledge City and Guangya people day and night.

The transformation practice with Guangya Holding Group as the core is not only the group's initiative to promote the high-quality development of the manufacturing industry and suffer in the trough of marketization, but also a key move to seize new opportunities in the field of aluminum application and realize the leap from the whole industry chain to the whole value chain.