Delivery Port:

Foshan, ChinaProduction Capacity:

700000 Tons/YearPayment Terms:

L/C, T/TMaterial:

Aluminum AlloyOpen Style:

as DesignsOpening Pattern:

HorizontalSurface Finishing:

FinishedStandard:

EN755Transport Package:

WoodOrigin:

ChinaFunction:

Heat Insulation, Soundproof, Anti-Theft, Airproof, Insect-proof, Dust-proof, Invisible, DecorationThermal Break Aluminum Extrusion Profile For Sliding Windows & Doors

Advantages of Guang Ya Thermal Break System

Specifications:

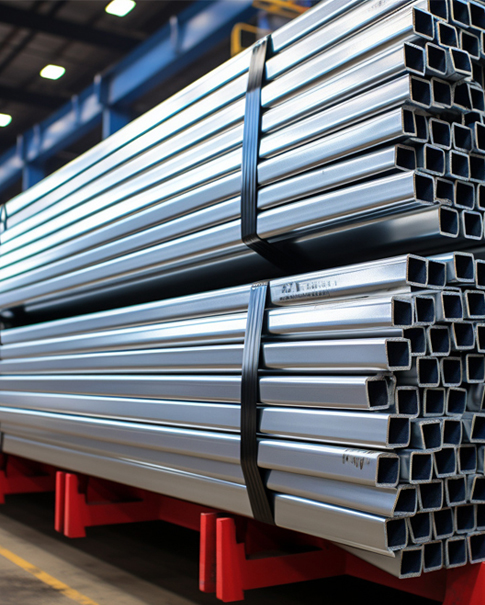

1) Product Name: Customized Extruded Aluminium Profile for Sliding Windows & Doors

2) Alloy: 6063, 6061, 6082, 6060, 6005, 6101, 6463

3) Length: Longest 8m (or upon clients' requests measurement the length).

4) Surface treatment: Mill Finish, Powder Coating, Anodization, Electrophoresis, Fluorocarbon, Wood Grain

5) Package Method: Transparent protection film on visible surface, several pieces packed with shrink bag.

6) Execute standard: ASTM B221, EN755, GB5237.

7) Quality control: 100 quantity inspectors.

8) Qualification: · ISO 9001: 2015 Quality Management System;

· ISO 14001: 2015 Environmental Management System;

· OHSAS 18001: 2007 Occupational Health and Safety Management System;

· EN 15088: 2005 Factory Production Control;

· QUALICOAT Quality Labels for Sulfuric Acid-based Anodizing of Aluminium;

· QUALICOAT Quality Sign for Paint, Lacquer and Powder Coatings on Aluminium for Architectural Application

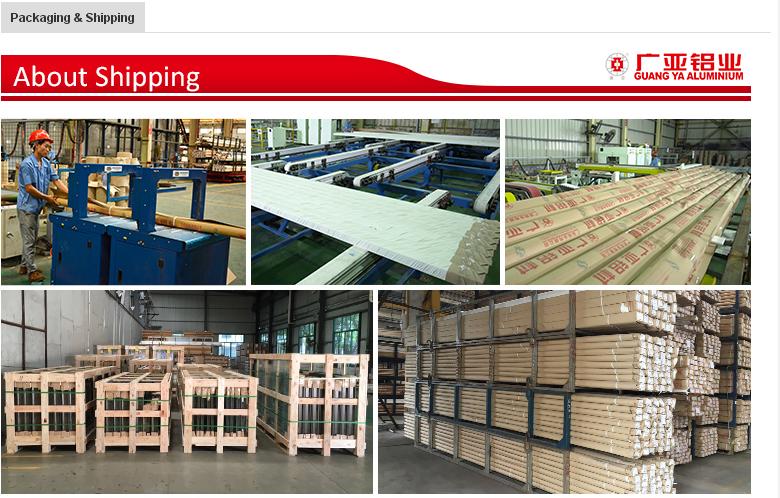

Before each batch of goods is shipped, Guangya will control the quality of the goods through strict inspection.

Guangya has a professional loading platform to ensure that your goods can be loaded into the container in good condition.

To show other products of the same type