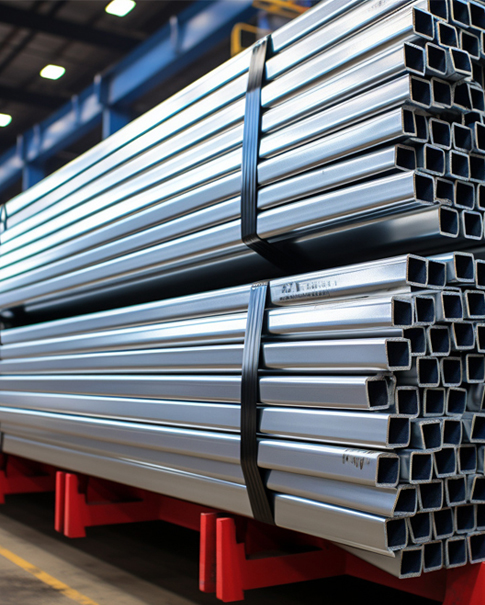

Aluminum profiles are aluminum materials with different cross-sectional shapes obtained by hot melting and extrusion of aluminum rods. The production process of aluminum profiles mainly includes three processes: casting, extrusion, and coloring. Among them, coloring mainly includes processes such as oxidation, electrophoretic coating, fluorocarbon spraying, powder spraying, and wood grain transfer printing.

Classification method for aluminum profiles

1、 It can be divided into the following categories according to its purpose:

1. Architectural aluminum profiles (divided into two types: doors, windows, and curtain walls)

2. Radiator aluminum profiles.

3. General industrial aluminum profiles: mainly used for industrial production and manufacturing, such as automated mechanical equipment, the framework of covers, and customized mold opening according to the requirements of various companies' mechanical equipment, such as assembly line conveyor belts, elevators, dispensing machines, testing equipment, shelves, etc., are mostly used in the electrical machinery industry and clean rooms.

4. Aluminum alloy profiles for railway vehicle structures: mainly used in the manufacturing of railway vehicle bodies.

5. Frame aluminum profiles, create aluminum alloy picture frames, and frame various exhibitions and decorative paintings.

2、 Classification by alloy composition

Aluminum profiles can be classified into alloy grades such as 1024, 2011, 6063, 6061, 6082, and 7075, with the most common being the 6 series. The difference between different grades lies in the different proportions of various metal components. Except for commonly used building aluminum profiles such as 60 series, 70 series, 80 series, 90 series, curtain wall series, etc. for doors and windows, there is no clear model distinction for industrial aluminum profiles. Most production factories process them according to the actual drawings of customers.

3、 Typical uses of different grades of aluminum alloys

1050: Extruded coils, various hoses, fireworks powder for food, chemical, and brewing industries

5050: Thin plates can be used as inner lining plates for refrigerators and refrigerators, as well as for automotive air pipes, oil pipes, and agricultural irrigation pipes; It can also process thick plates, pipes, bars, irregular materials, and wires, etc

5154: Welded structures, storage tanks, pressure vessels, ship structures and offshore facilities, transport tanks

6010: Sheet: Automotive Body

6061: Various industrial structures with certain strength, weldability, and high corrosion resistance are required, such as pipes, rods, shapes, and plates for manufacturing trucks, tower buildings, ships, electric vehicles, furniture, mechanical parts, precision machining, etc

6063: Industrial profiles, building profiles, irrigation pipes, and extruded materials for vehicles, racks, furniture, fences, etc

6066: Forgings and welded structural extrusion materials