After fluorocarbon treatment, aluminum profile has excellent corrosion resistance and weather resistance, can resist acid rain, salt mist, and various air pollutants, has excellent cold and heat resistance, can resist strong ultraviolet radiation, and can maintain long-term non fading and non powdering, and is durable

Delivery Port:

Foshan, ChinaProduction Capacity:

700000 Tons/YearPayment Terms:

L/C, T/TMaterial:

Aluminum AlloyOpen Style:

as DesignsOpening Pattern:

HorizontalSurface Finishing:

FinishedStandard:

EN755Transport Package:

WoodOrigin:

ChinaFunction:

Heat Insulation, Soundproof, Anti-Theft, Airproof, Insect-proof, Dust-proof, Invisible, DecorationCheap Factory Price Industrial Aluminium Curtain Wall Profile

Aluminum profile is one of the most common use building materials in curtain wall. The curtain wall is located on the exterior surface of the building and is often affected by unfavorable factors of the natural environment, such as the sun, rain, sand erosion. Therefore, it requires sufficient weather resistance and durability of curtain wall materials. With weatherproof, anti-sun, anti-theft, anti-impact, thermal insulation and other functions. The aluminum profile for curtain wall should be surface anodized, electrophoretic painted, powder sprayed or fluorocarbon paint spray treatment to ensure the durability of the curtain wall.

Business Type

Manufacturer

Material Grade

6000 series Aluminium Alloy

Standard

GB 5237-2008, ASTM B221, EN755-9, EN12020, JIS.

Surface Treatment

Mill finish, Powder Coating, Anodizing, Wooden grain coating, Polishing, Eletrophoresis, PVDF, Sanding blasting, etc.

Further Process Ability

Drilling, Bending, welding, precise cutting, punching, fabrication of finished products, etc.

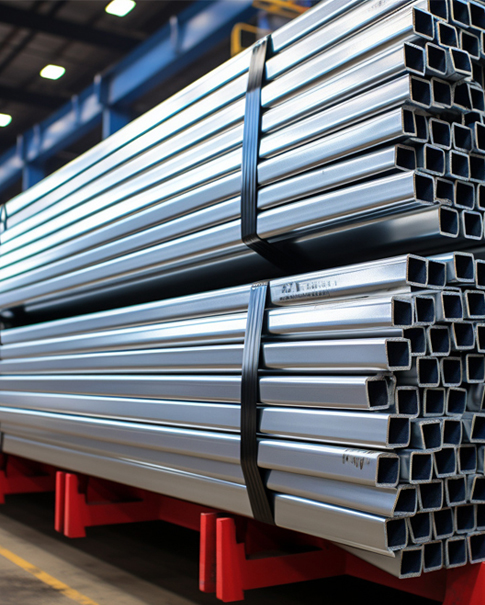

Specification

Alloy: 6063, 6060, 6005, 6061, 6082, etc.

State: T4-T6.

Length: 3m-12m.

Wall thickness: >0.7mm.

Anodizing thickness: 10, 12, 15, 20, 25 microns.

Powder coating thickness: >40 microns, >60 microns.

Tensile strength: >16mpa. Customized standard.

Yield strength: >110mpa. Customized standard.

Extensibility: >8%. Customized standard.

Hardness(HW): >8. Customized standard.

Designs and tolerances

As per drawings or samples.Tolerance will be shown on each drawing

Moulds / Dies

Making moulds and producing as per desgined drawing

1. Using our existing moulds, no extra charge

2. Using Client drawings, cutting new mould. The mould fee will be paid back when quantity reach target in 1 year.

Application

ALL CUSTOMIZED. Windows and doors, curtain wall, fence, standard shape ( tube, pipe, channel, angle, bar, T, C, U, etc. ), industrial ( heat sink, solar frame, conductor rail, car, cellphone, etc. ), kitchen cabinet, wardrobe, railing, furniture, office partition, roller shutter, sun room, etc.

Certificate

CE, ISO9001,OHSAS18001,ISO14001,Qualanod, Qualicoat.

Quality Control

1. Inspection at Site.

2. Inspection Before Shipping.

3. Testing Machine.

Packing

Protective film sticked on profile's visible surface, foam paper interleave each piece.

Adequate pieces wrapped in small bundle by shrink plastic film / kraft paper. Labels with the client's logo on both end of the package.

Bulk load into container. Or packing in big bundle by wooden frame, put on steel rack.

Lead Time of Goods

15-20days

Lead Time of Moulds

7-15days

Normal Order Sequence

1.Conform the drawings, colors and price;

2.Pay the mould fee and we start to make moulds;

3.We send samples to you for your confirmation;

4.Make the payment of 30% deposit, we start production;

5.Delivery.

Payment Term

T/T, L/C at sight.

Container type

20'GP, 40'GP, 40'HQ, 45'HQ.

Minimum order quantity

1x 20'GP FOB for FCL or 5 TONS EXW for LCL.

Origin

Foshan City, Guangdong Province, China.

Before each batch of goods is shipped, Guangya will control the quality of the goods through strict inspection.

Guangya has a professional loading platform to ensure that your goods can be loaded into the container in good condition.

To show other products of the same type