Delivery Port:

Foshan, ChinaProduction Capacity:

700000 Tons/YearPayment Terms:

L/C, T/TMaterial:

Aluminum AlloyOpen Style:

as DesignsOpening Pattern:

as DesignsSurface Finishing:

Anodic Oxidation, Mill FinishStandard:

EN755Transport Package:

WoodOrigin:

ChinaFunction:

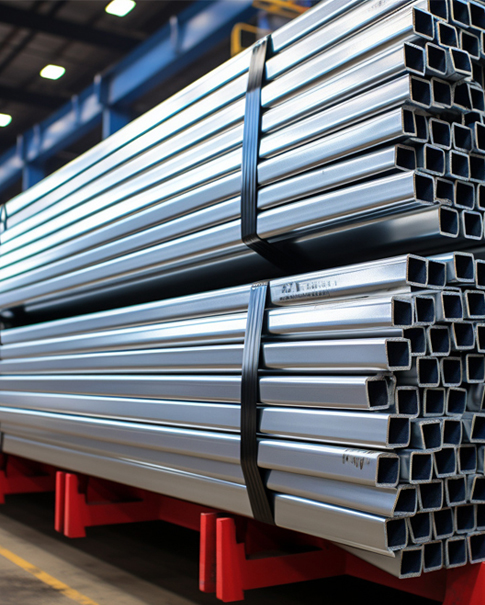

Dissipate heatIndustrial Radiators Aluminium Profiles

The aluminum profile radiator has the characteristics of beautiful appearance, light weight, good heat dissipation performance and good energy saving effect. The surface of the processed aluminum profile heat sink is anodized for surface treatment to increase the corrosion resistance, wear resistance and appearance of the aluminum.

Aluminum extrusion profile heat sink are mainly made of high pressure cast aluminum and tensile aluminum alloy. Its main advantages are:

1. The heat dissipation of the aluminum profile heat sink is good, and the energy-saving features are very obvious. In the same room, if the same size radiator is used, the number of aluminum casts is less than that of steel.

2. Aluminum profile heat sink has good oxidation and corrosion resistance without adding any additives. The principle is that once aluminum encounters oxygen in the air, it will form an oxide film. This film is tough and dense, preventing further on the bulk material.

Specifications:

|

Business Type |

Manufacturer |

|

Material Grade |

6000 series aluminium alloy |

|

Standard |

GB 5237-2008, ASTM B221, EN755-9, EN12020, JIS |

|

Surface Treatment |

Mill finish, Powder Coating, Anodizing, Wooden grain coating, Polishing, Eletrophoresis, PVDF, Sanding blasting, etc |

|

Further Process Ability |

Drilling, Bending, welding, precise cutting, punching, fabrication of finished products, etc |

|

Specification |

Alloy: 6063, 6060, 6005, 6061, 6082, 6101, 6106, etc State: T3-T8. / Wall thickness: >0.7mm |

|

Designs and tolerances |

As per drawings or samples.Tolerance will be shown on each drawing |

|

Moulds / Dies |

Making moulds and producing as per desgined drawing 1. Using our existing moulds, no extra charge 2. Using Client drawings, cutting new mould. The mould fee will be paid back when quantity reach target in 1 year. |

|

Certificate |

CE, ISO9001,OHSAS18001,ISO14001,Qualanod, Qualicoat |

|

Payment Term |

T/T, L/C at sight |

|

Packing |

Kraft paper, protective film, plastic shrink, pearl wool, box, wood frame |

Production Equipments :